Analyze & Optimize Process Performance Over Time

Strong yield increases overall equipment effectiveness, revenue, and profits. It’s critical to understand how to improve production quality and provide teams with the right information at the right time. With the Dataiku Parameters Analyzer Solution, add process parameters through a web application, analyze historical production processes, set targets, find optimum performance ranges, and scale across different production types.

Analyze Manufacturing Operations & Processes

Quickly ingest historical process parameters and quality metrics for all production activities with the Dataiku App. Turn historical performance into trusted analytics and ensure production quality.

Understand Trends & Define Ideal Outcomes

Define targets and select relevant quality metrics from your manufacturing process to review in the Dataiku App. Dig deeper and filter by analysis period and acceptable range for given quality indicators and processes.

Connect Process Parameters & Quality

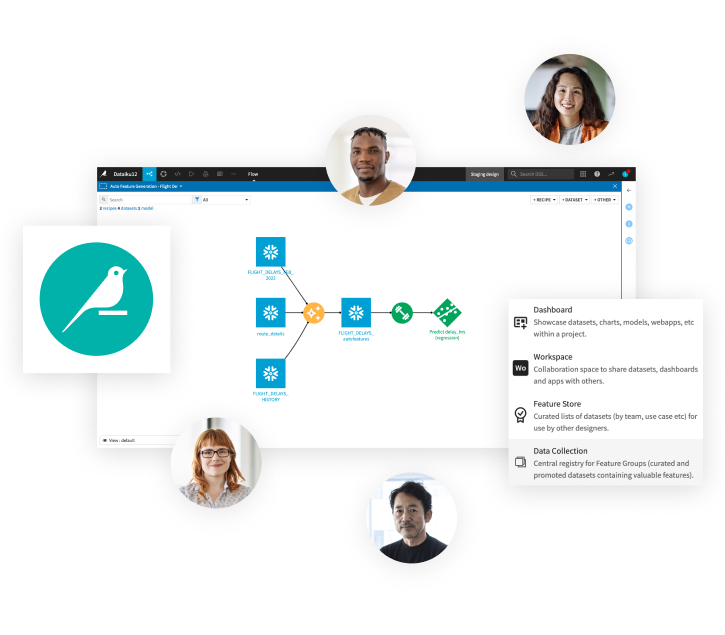

Choose specific process parameters and reveal how each might be impacting quality targets. Make adjustments through a visual interface to guide decision-making and collaboration between process engineers and technicians.

Maximize Results & Scale Quickly

Find critical process parameters and ideal parameter ranges to improve manufacturing. Then easily scale across quality indicators, production lines, and sites to balance consistency and capacity.

Get Deeper Predictive Insights

Supplement expertise with robust data analytics to enhance decision accuracy and process outcomes. Find patterns through deep analysis, then use new findings to empower engineering and operations teams with data-driven approaches.

Answer Key Process Analysis Questions

The Dataiku Parameters Analyzer Solution helps answer a broad range of questions like:

- How can I identify the relationships between my input and outcome?

- How do I track process changes over time? How can I achieve the best quality control?

- Which production parameters are impacting production targets the most?

- I have different assets. How do I develop consistent analytics?

- How can I reduce scrap and improve product yield?

- What are the optimal settings for my most impactful parameters?

Better Outcomes Through Process Optimization

Build a repeatable, scalable and automated process for understanding critical control parameters and their ranges. Use machine learning and AI to mine data, understand parameter adjustment, and enhance data-driven work in manufacturing operations. Put data to work to improve yield and optimize quality.

The Total Economic Impact™️

Of Dataiku

A composite organization in the commissioned study conducted by Forrester Consulting on behalf of Dataiku saw the following benefits:

reduction in time spent on data analysis, extraction, and preparation.

reduction in time spent on model lifecycle activities (training, deployment, and monitoring).

return on investment

net present value over three years.