Business Overview

Drilling represents the culmination of an intensive process; only by drilling a well can a prospect be validated. As the bit bores deeper into the earth, each additional length of drillpipe is connected to the previous joint, and the drillstring grows progressively longer. Drilling fluid, or mud, is pumped downhole to cool and lubricate the bit. The bit’s cutting surfaces gradually wear down as they grind away the rock, slowing the rate of penetration (ROP).

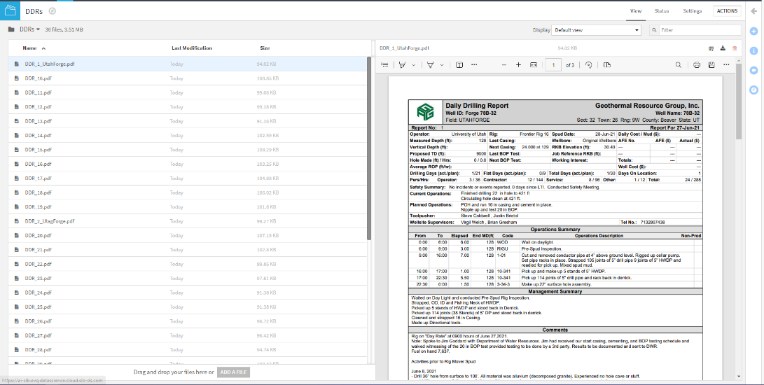

Drilling Engineers typically spend significant time in analyzing Daily Drilling Report (DDR) to perform offset well analysis manually. DDR is a detailed record of the drilling operations performed at a well site during a 24-hour period. It contains important information such as the drilling progress, the equipment used, the geological formations encountered, and any problems or incidents that occurred during the drilling process. Offset well analysis is a technique used in the industry to analyze the geological characteristics of nearby oil and gas wells, known as offset wells, to gain insights into the potential events likely to be encountered while drilling a new well.

Since DDRs are mainly stored as PDF files, manually extracting valuable information from PDFs is a long, painstaking, and error-prone task that cannot be scaled easily. Automating this process allows drilling engineers to gain insights from benchmarking drilling performance from offset wells to gain a fair understanding and plan for risks on the current drilled well; to analyze the bit performance of offset wells by choosing the best bit to optimize ROP value; and to perform non-productive time analysis, and visualize time breakdowns.

Highlights

- Drilling engineers can make data-backed decisions about effective risk management, bit selection, and well-time estimation….

- Transform Daily Drilling Reports into actionable insights by extracting casing summary, well summary, bit summary, and operation summary…

- Extracted insights can be used, analyzed, and visualized through customizable dashboards.

- Gain insights into multiple aspects, such as benchmarking drilling performance from offset wells and the bit performance to optimize ROP value and perform NPT analysis.

Structured Dataiku flow

The project has the following high-level steps. First, the Casing Summary – Input your DDRs in PDF, then run visual and code recipes to get: casing size, casing depth…Second, the Well Summary – run visual and code recipes to extract: Well ID, report number, report for, spud date, measured depth, and average ROP,… Third, the Bit Summary - run visual and code recipes to extract: make, model, section size, in-depth, mudflow, … Fourth, the Operations Summary - run visual recipe to extract: start time, end time, end MD, code, operations description, and non-productive time (NPT)….. Lastly, the Visualization using the Power BI dashboard.

DDRs reading and insights generation

Python libraries are used to read PDF files; all the files in pdf format are then converted and stored in Excel format. A code recipe gets the information of the required sections from the Excel files. The data of each section is stored in new datasets and then cleaned, filtered, and modified.

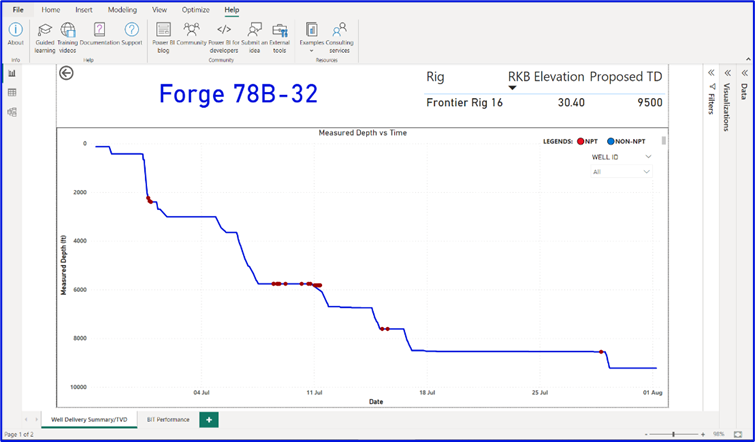

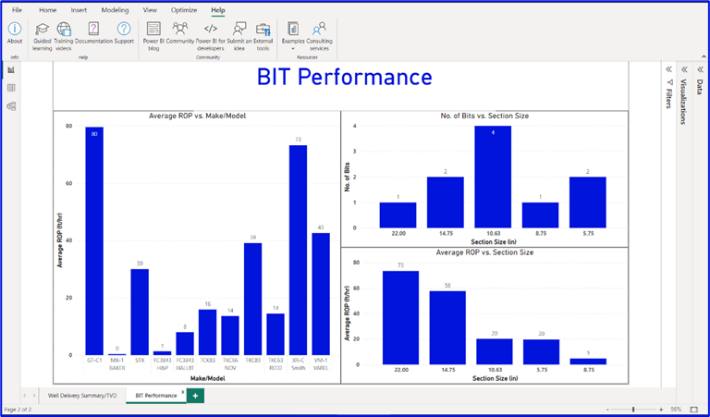

Output Visualization

Various rich visualization dashboards can be used, depending on where they need to be hosted. In this example, Power BI was used. Among the outputs are: Measured Depth vs. Time; Average ROP vs. Make/Mode; Average ROP vs. Section Size; and No. of Bits vs. Section size.

Repeatability and Customization

Daily drilling reports come in many different variations that will change depending on the customer, drilling type, operation area, formation type, etc. This workflow should be customized for the new structure of input DDR. The processing logic for the sections to be extracted needs to be adjusted based on the new input DDRs. Once the workflow is modified to the desired format, the changes can be visualized by refreshing the dashboard. The dashboard can be customized to visualize additional insights.